- The process sequence of injection molding is,

- Close the mold and lock the mold.

- Injection, the molten plastic is filled into the mold.

- Keep the pressure and use the plastic in the cavity as the final compensation pad.

- The plastic fluid cools and solidifies.

- Plasticization measurement, cooling time melts the next mold storage material.

- Open the mold.

- The cooled finished product is ejected, and the robot is taken out.

Injection molding is used to manufacture many things in various industries, such as medical equipment, biotechnology, aerospace, food container packaging, cosmetic container packaging, automotive industry, semiconductor, industrial and consumer electronics, new innovation industries, and large Most other plastic products. Injection molding is the most common method of part manufacturing. It is ideal for producing large quantities of identical objects. The advantages of injection molding are high productivity, repeatable high-precision tolerances, the ability to use multiple materials, lower labor costs, minimal waste loss, and almost no secondary machining parts after molding. Some disadvantages of this method are expensive equipment and mold investment, potentially high operating costs, and the need to design moldable process parts.

Manufacturing using the injection molding process usually requires a lot of mold upfront investment costs. That’s why it is particularly important to design the mold the first time, rather than having to start again after a serious defect is discovered. Defects related to mold manufacturing processes or materials are often easier to solve and lower cost. But regardless of the cause, defects in molded products can seriously damage your profits.

Under the same production conditions, there are various factors of change in production, and the production process will definitely change a lot. Malfunctions such as machinery or equipment are also a major factor affecting product quality variation. Others, such as material batch variation, blocked mold vents, rusty cooling water channels, and reduced cooling efficiency are all.

Therefore, in order to prevent the product quality from deviating from the customer's requirements for quality standards, it is necessary to do a good job of control during the production process. Once the quality is found to be defective, the cause should be immediately corrected in time to maintain product quality above a certain level.

EwellPlastics has accumulated 30 years of experience in plastic injection molding technology and precision mold manufacturing, focusing on technological advancement to meet the high-quality needs of customers in the medical device industry, and fully familiar with the causes of common injection molding defects, so that preventive measures can be taken to prevent defective products in the future. To ensure that your products meet the needs of customers and the market.

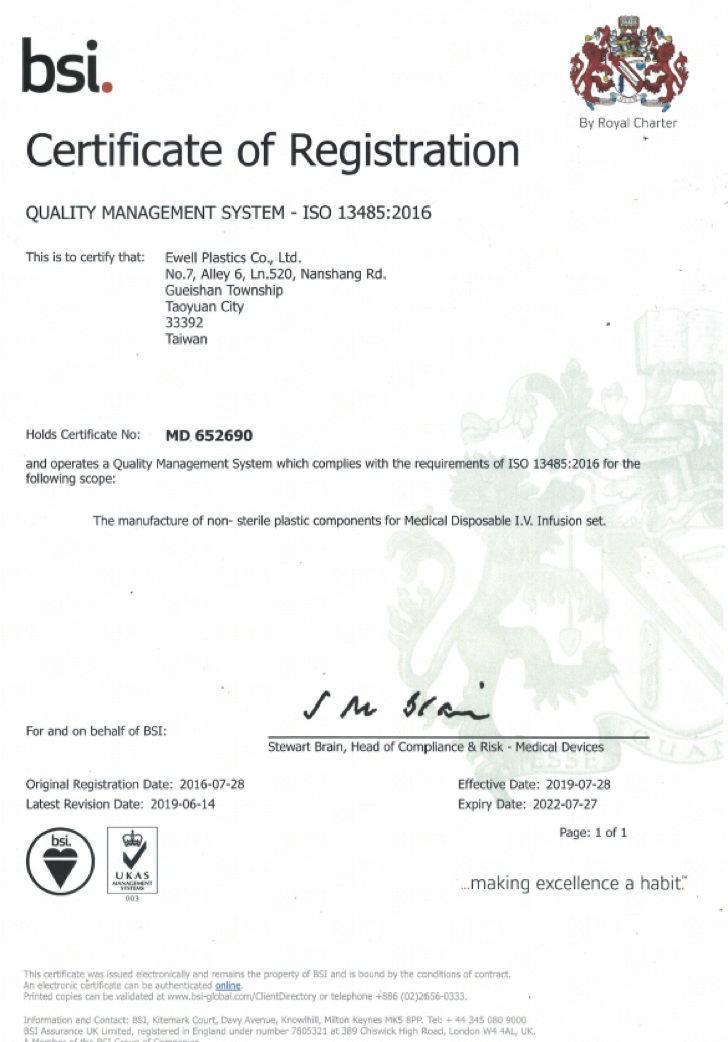

At EwellPlastics, we assume the responsibility of providing our customers with the best quality products on time. EwellPlastics has passed ISO 13485:2016 certification, EwellPlastics meets the expectations of the most demanding medical device manufacturers. Whether it is a problematic customer-supplied transfer mold or a complex new product, EwellPlastics can provide the quality you expect.

When EwellPlastics was granted the opportunity to develop molds for customers, the molds were designed by people who work and breathe in injection molding. From the perspective of injection molding, the design of runners, gates, and exhaust air escapes must be carefully designed to ensure that molded parts without visible and functional defects can be produced. Similarly, the cooling system is at the forefront of the mold development process. We continue to pursue technological progress in plastic injection molding and precision mold manufacturing to help us fulfill our mission of providing high-quality injection molding services and delivering them to customers on time.

EwellPlastic's quality and quantity measurement and control

- ISO 13485: 2016 certification

- The quality plan can be tailored according to the needs of individual customers,

- And other custom quality inspection procedures.

- Complete annual internal audit schedule

Ex.

- Material loss

- Equipment operating cost

- Labor hours

- Delay in delivery

- Affect customer production line operation

- Cash flow

- Damage to goodwill

We carry out the production process in the injection molding workshop that is controllable under the ISO13485 medical equipment quality management system. All injection molding equipment has passed an extensive installation qualification agreement and is regularly calibrated. Develop procedures and agreements to ensure the quality of each batch of products.

Throughout the production process of the parts, the plastic raw materials will be accurately controlled to ensure compliance with the ISO manufacturer's specifications. All employees have received the correct technical training of ISO13485 system personnel. We also use the powerful IQMS ERP system to provide IPQC monitoring and inventory control. Ewell Plastics' injection molding machine equipment specifications range from 80 tons to 140 tons for precise production services.

EwellPlastics is committed to providing our customers with high-quality and high-value products under the premise of complying with applicable laws and regulations. By using reliable and efficient systems and processes, we will deliver safe and effective products on time at reasonable costs. We will build strong relationships with customers and strive to continuously improve everything we do.

ISO 13485 is the most widely used international standard for quality management in the medical device industry. The ISO 13485 standard issued by the International Organization for Standardization (ISO) is an effective solution that can meet the overall QMS requirements of the medical device industry.

The adoption of ISO 13485 provides manufacturers with a practical basis for solving the EU Medical Device Directive (MDD), EU Medical Device Regulation (MDR) and other regulations, and demonstrates their commitment to the safety and quality of medical devices.

ISO 13485 applies to any organization that is partially or fully involved in the life cycle of a medical device. Unless explicitly stated, the requirements of this standard apply to organizations regardless of their size and type.

Compliance with regulatory requirements and customer expectations, verification can increase access to more global markets Ensuring that products can meet regulatory requirements when entering the market is the key to maintaining a competitive advantage for medical device manufacturers.

Passed ISO-13485:2003 medical equipment quality system certification in 2016.