EwellPlastics Core Capabilities

Precision Injection Molding

Precision Mold ODM

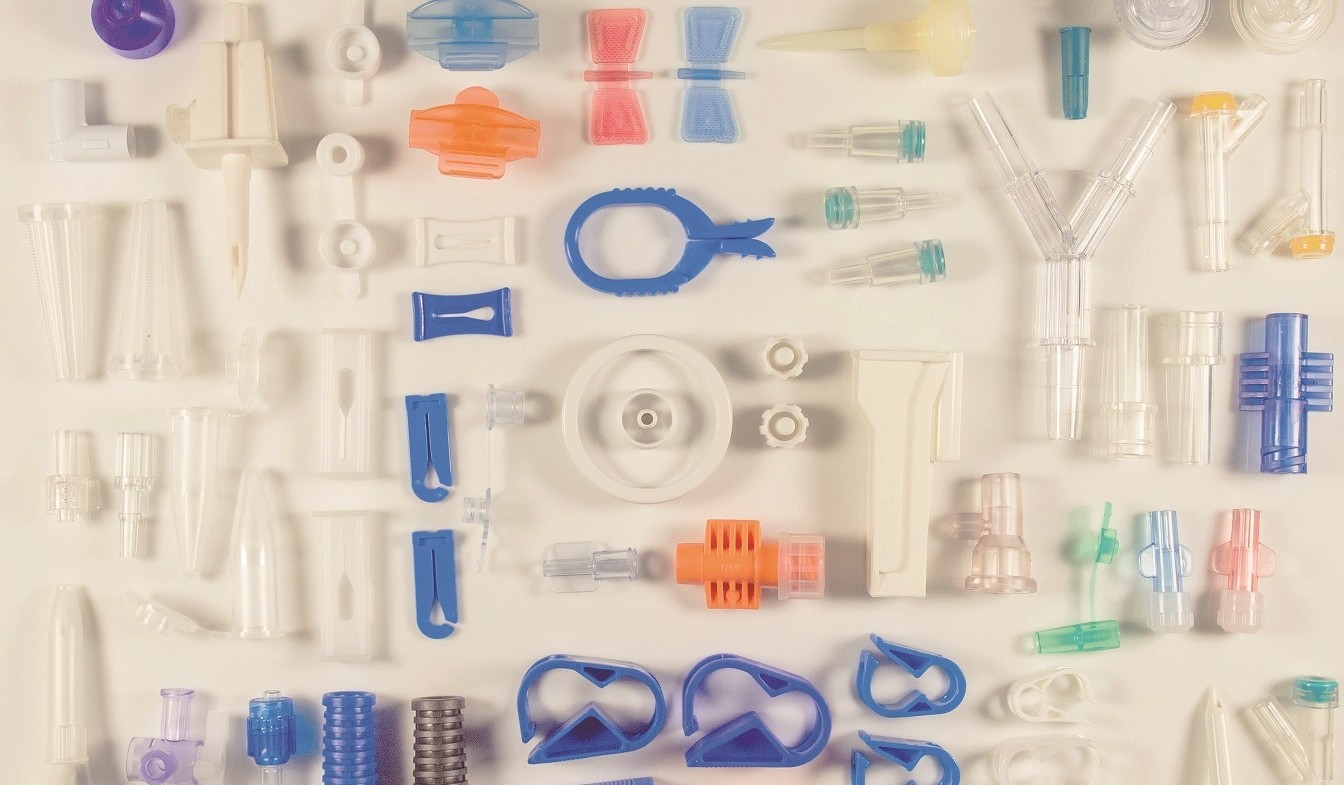

Medical Device Component

Core Capabilities

1.Plastic Injection Molding

Our plastic molding plant is composed of 10 plastic injection molding machines, ranging from 80 tons to 140 tons. Under a well-controlled production process, our plastic injection molding machines can be produced for medical device and biomedical startups. Small batch parts or mass production.

2.Precision Mold ODM

Multiple plastic mold making equipment: CNC milling machines, lathes, grinders, electric discharge machines, segmentation machines, grinders, laser repair molds, argon welding...etc.

3.Medical Device Component

Ewell Plastics specializes in the collaborative development and manufacturing of various plastic medical device and consumables. At the same time, it also develops its own medical materials-drip infusion consumable parts (ISO594 Luer Connector, Clip, Clamp), providing innovative plastic manufacturing solutions for the medical and biotechnology industries !

Service Process

Plastic ODM service inquiry/quotation

Customer can provide

- Sample or drawing.

- Plastic product design.

- Plastic production demand.

- Quality requirements and other information.

Drawing file format

- 2D (CAD, PDF)

- 3D (IGS, STP)

DFM

Plastic related feasibility manufacturing analysis

- Reverse Engineering

- 3D Printing

- Mold flow analysis

- Design change adjustment

Plastics Mold ODM

Design

- Mold Flow Analysis

- 3D Part Design Modeling

- Siemens UG NX

- Autodesk AutoCAD

Manufacturing

- 3D Contour Programming

- High-Speed CNC-Machining

- CNC-EDM

- Complete Tool Build Inspection to Customer Standards

- Rigorous Mold Sample Tryout

Plastic Injection Molding

Ewellplastics provides injection molding manufacturing with general or medical grade plastic raw materials.

Ex:PVC、PE、PP、ABS、AS、PMMA、PC、PCTG、PA-6、PA-66、PA-12、PBT、POM、TPE/TPR、TPV、TPU等。

Quality & Metrology

ISO 13485:2016 certificated.QA quality management system production process.

- IQC/IPQC/FQC/OQC/MQC

- 2.5Dimage mapping

- instrument. *Various types of precision

Plastic Products

Ewellplastics is committed to the continuous improvement of product quality,in line with the relevant regulations and standards of medical equipment and equipment,and customers' high-standard quality requirements.